Page 2 of 13

Re: trotters new sammy

Posted: Sun Feb 19, 2012 10:14 pm

by ianedwards

when i took mine apart, i wondered how the cab didnt blow away in the wind while bringing back on the trailer, there was so much rot round the mounts. never mind done now.

Ian

Re: trotters new sammy

Posted: Tue Feb 21, 2012 9:20 pm

by dazerede

by the way is this sammy japanese

Re: trotters new sammy

Posted: Tue Feb 21, 2012 9:50 pm

by dan_2k_uk

yeah 1990 Jap Samurai jx

Re: trotters new sammy

Posted: Tue Feb 21, 2012 10:49 pm

by dazerede

just thinking becouse ive just noticed that the front looks a bit diffrent where the front shackles are.

Re: trotters new sammy

Posted: Tue Feb 21, 2012 11:17 pm

by trotter

That's the calmini shackle reversal kit (not standard shackles)

Re: trotters new sammy

Posted: Tue Feb 21, 2012 11:17 pm

by dan_2k_uk

Its got a calmini shackle reversal kit fitted.

Dan

Re: trotters new sammy

Posted: Sun Feb 26, 2012 9:00 pm

by trotter

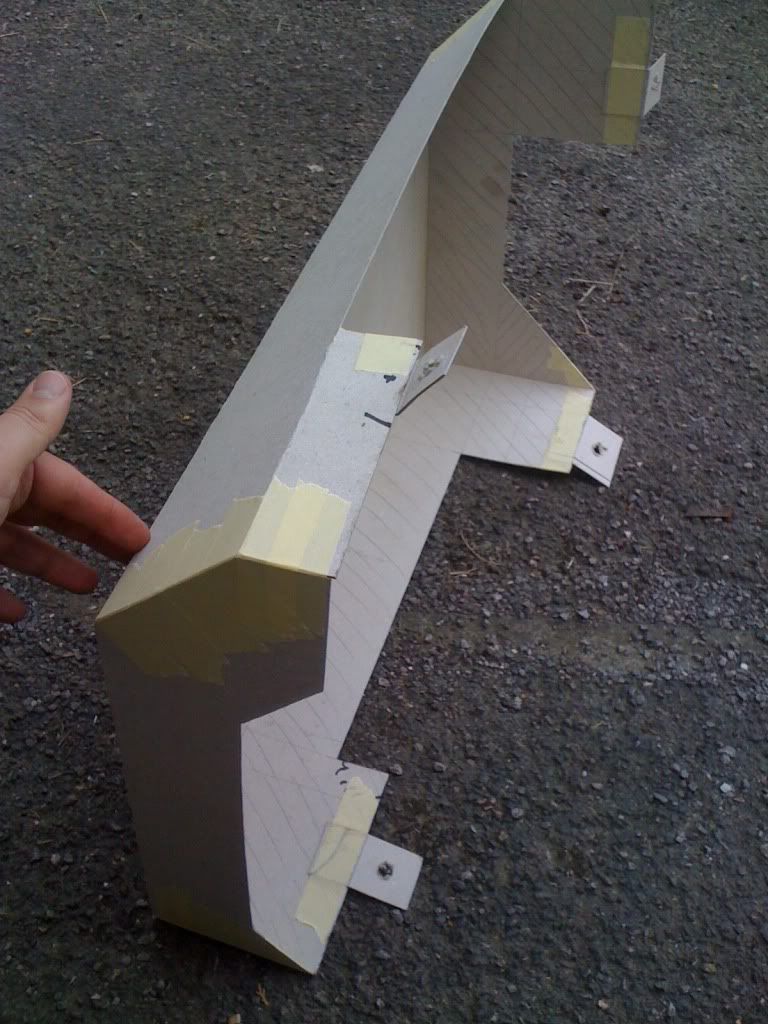

Right quick update had a busy weekend cutting big holes in the floorpan behind the rear seats and in the passenger footwell.

When I lifted the body off 2 of the body mount studs had rotted through and weren't attached to the body anymore, so I've had to plate the floorpan up and drill through and re insert the studs then tack them in place before plating over the top on the inside.

Only got a couple of pictures (i'l take some more tomorrow and post up) as I've been cracking on making the best of the nice weather this weekend.

Thanks to dan_2k for his help/piss taking

Re: trotters new sammy

Posted: Sun Feb 26, 2012 10:07 pm

by ianedwards

Same here, it's been to nice not do do any work on the sj, I had to do all the mounts on mine, rotted away, all of them

Ian

Re: trotters new sammy

Posted: Mon Feb 27, 2012 7:02 pm

by trotter

Re: trotters new sammy

Posted: Mon Feb 27, 2012 7:47 pm

by trotter