Have some updates with pics

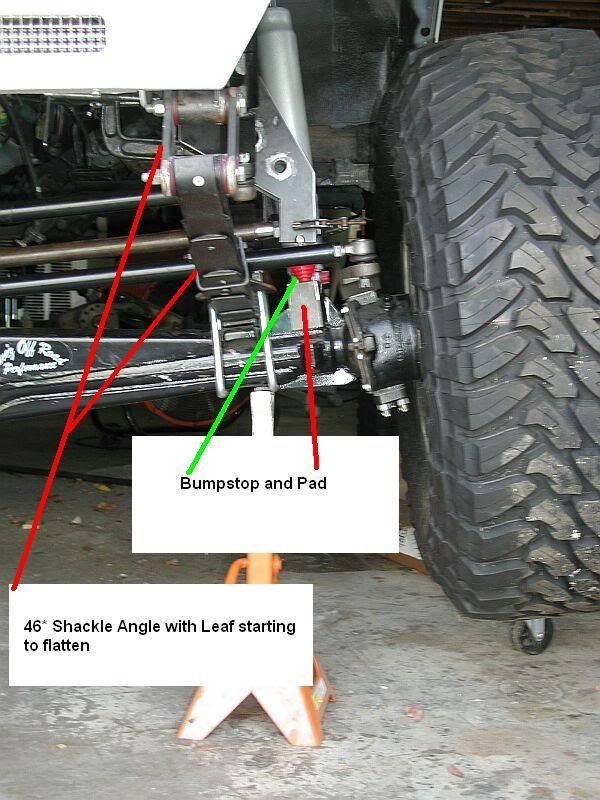

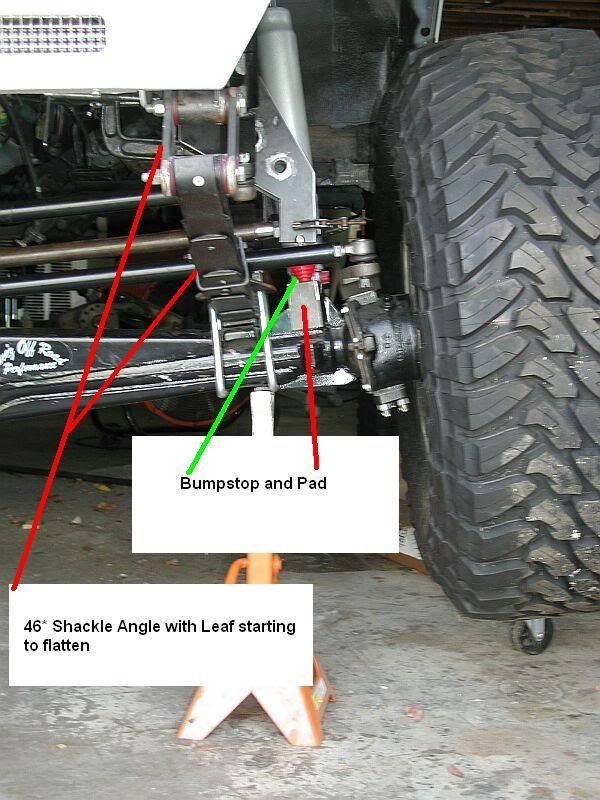

Doing a little flexing to get the proper setting for the DS suspension components. The front shackle is at

46* and the DS leaf is getting close to a flat position. This is where I will set the bumpstop contact point.

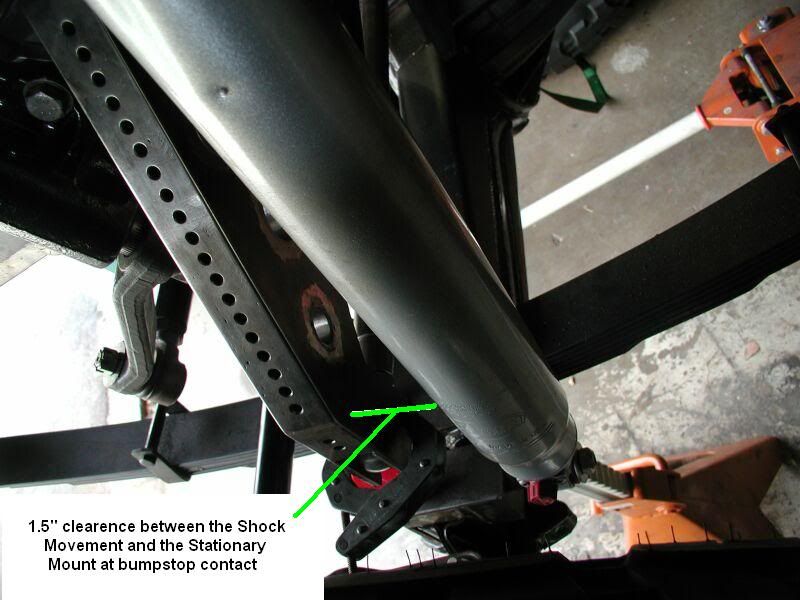

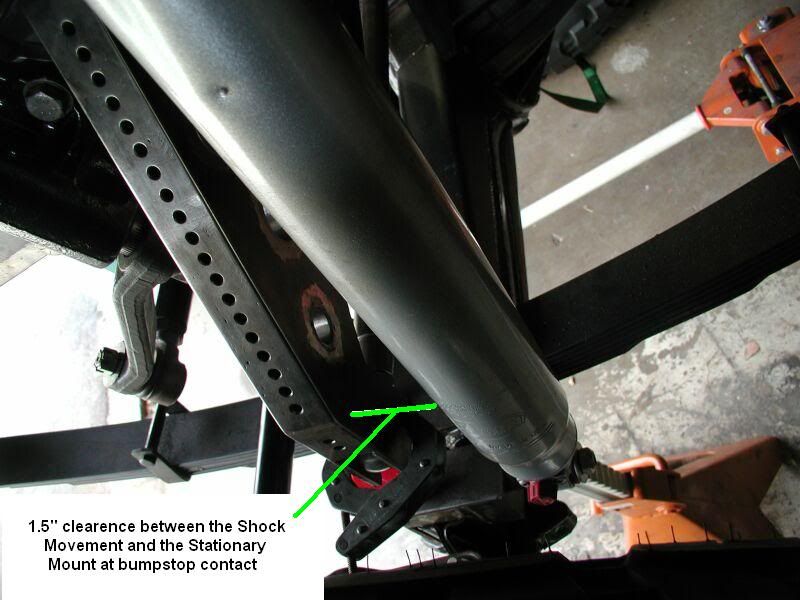

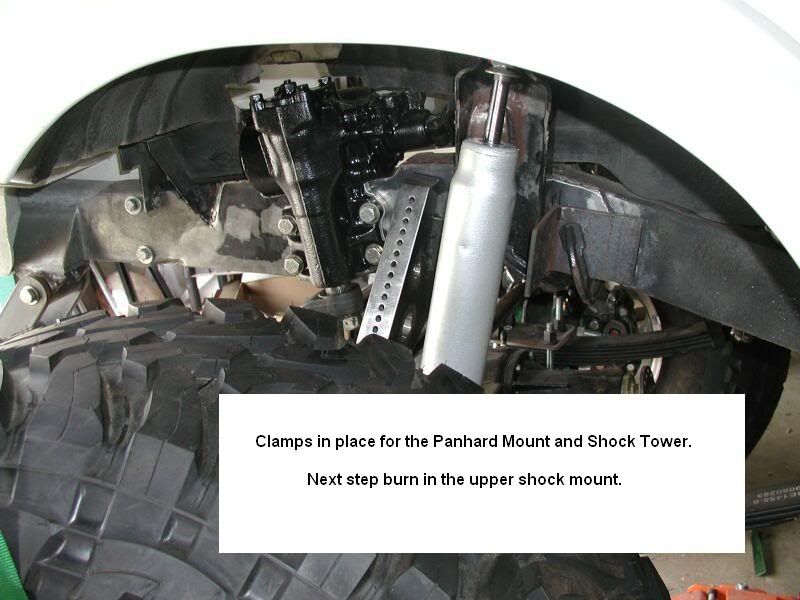

The shocks still have 2” of up travel to go. The clearance between the Panhard Mount and the (shock forward movement is 1.5”).

To be honest I was more concerned of the shock hitting the mount at full flex because the shock moves forward and the mount is stationary. Worked out and even have enough room for the head of a ¾ bolt to fit.

Loaded the weight of the motor back in the engine bay also. This brought my steering rod angles in at

3*. Shouldn’t see any bumpsteer with those angles.

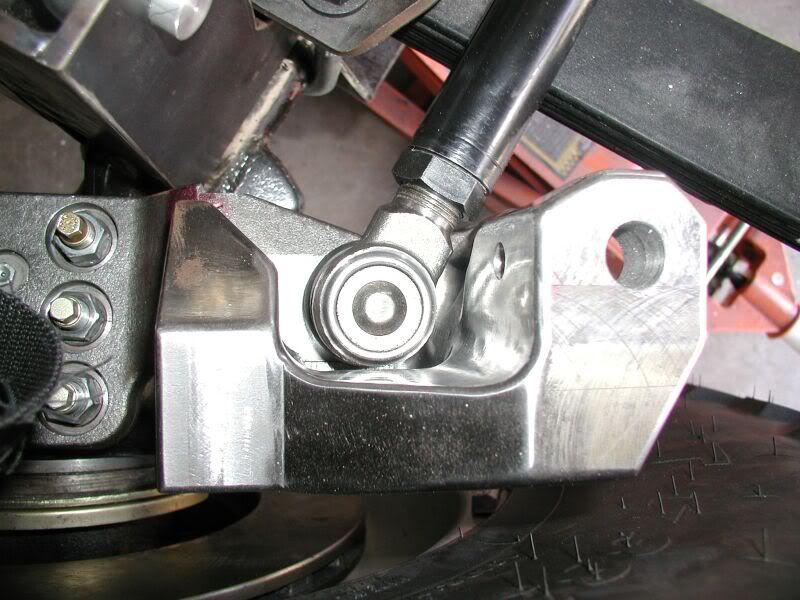

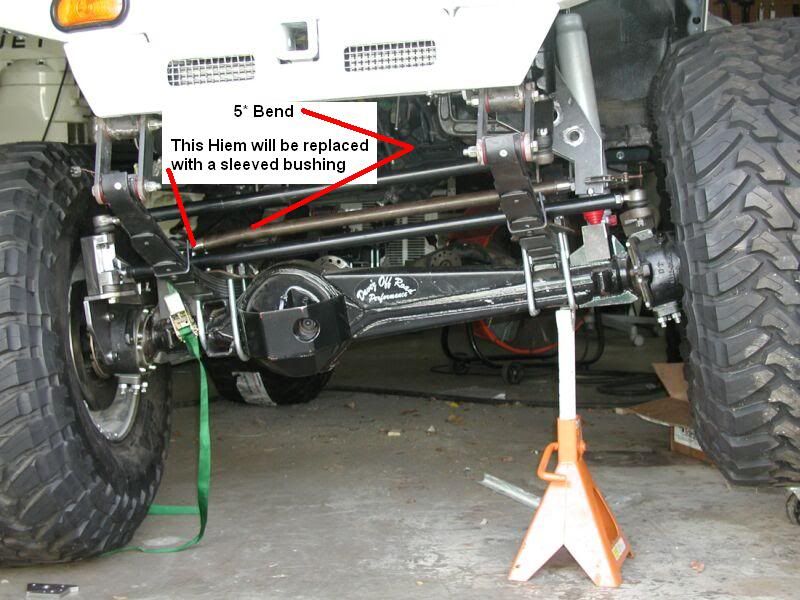

The suspension parts have been made for a while now. They are now going through the altering stage for better clearances or better ideas as more of the parts are added and watching the suspension cycle.

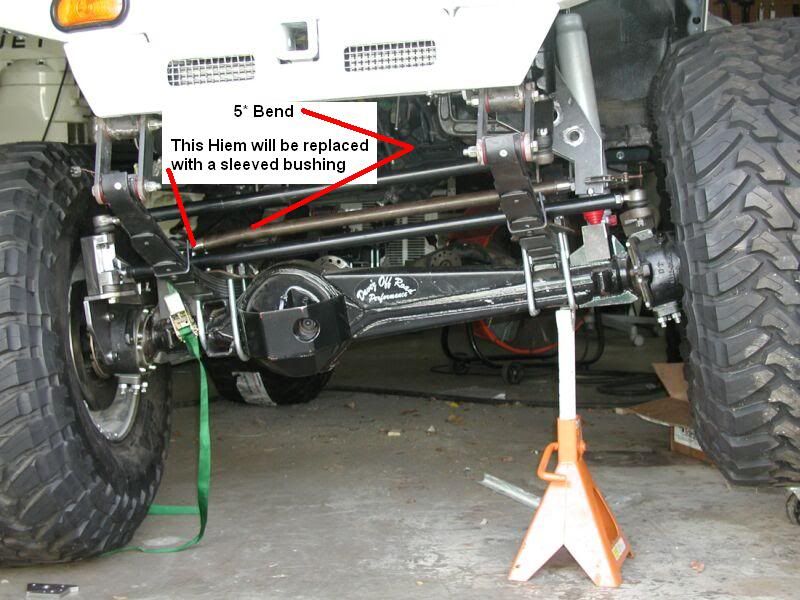

I have decided to remove the Heim joint from the PS Panhard Bar. This will be replaced with a sleeve to accept a pair of leaf spring bushings welded to the Panhard Bar.

The reason for the change:

The Panhard Bar has a

5* bend in it and it tends to want to flop back and forth this will eliminate this issue. Really didn’t want to hear that noise when I was driving either. This will also make what movement there is with suspension cycling not as rigid.

This means I will have to modify the PS Panhard Bar Mount for the larger sleeve bushing and offset the front portion for new alignment.

These types of changes add a lot of time probably why it seems like there isn’t much progress made. There are a lot of factors to take into consideration especially when you start cycling the suspension. Better to catch the issues now then be non flexible with your design and have to do it all over again later.

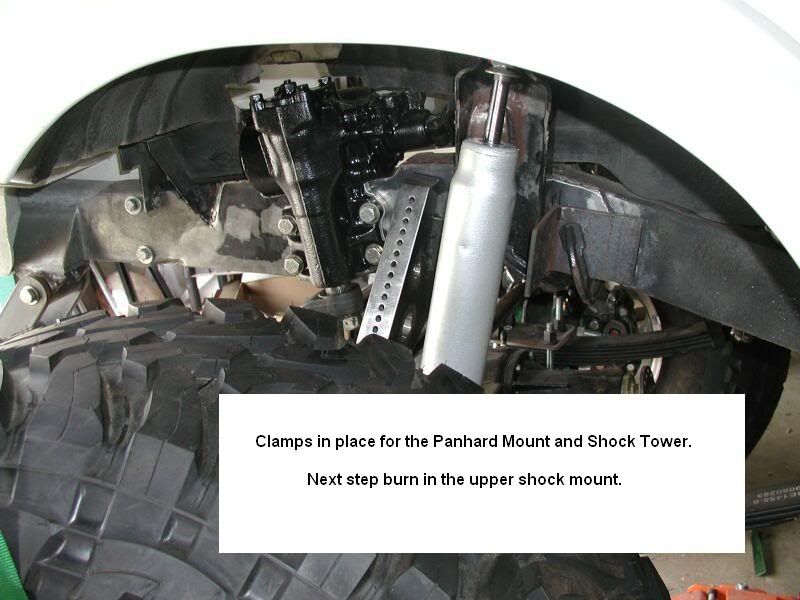

This particular area of the build has taken me 6 month to engineer and make the parts. It's finally time to start burning in parts.