Here is my build thread by request.

I wanted to start off by saying after posting 3 other build threads that I understand that there are some that think something like this is impractical. I also am aware that the sight of this type of Novelty Rig tends to offend people as well.

To help eliminate a few pages of the usual questions and statements pertaining to:

It is too clean you need to get it dirty.

Why would you build a Rig for street use only?

It’s too tall and it will flop over.

I hope this explanation helps:

The build was started to give me something to do as rehab because I had experienced an extreme heath crisis 12 years ago. I’m able to go over to my shop and putter around a few hours a day to work on the Rig. I did enjoy doing many things that I’m no longer able to do any more and one of them was wheeling. It took awhile to come to terms with this and I am happy to just be able to build something.

Now if you don’t focus so much on the shiny and purdy stuff. You will notice that I have fabbed quite a few parts for the build and the motor. I also will show in detail how to make and use the some of the parts.

There will also be times that I will share tips and tricks on several things on the Zooks as well. Please be patient and give it some time and you will probably enjoy the build. As I mentioned earlier I have 3 other build threads and they all start off a bit odd but they seem to appreciate the material more and more.

Thanks

On with the build. I will start with the before and in process pics being the Rig is still being built.

Before completely stock from California

Completely stripped and repainted inside and out.

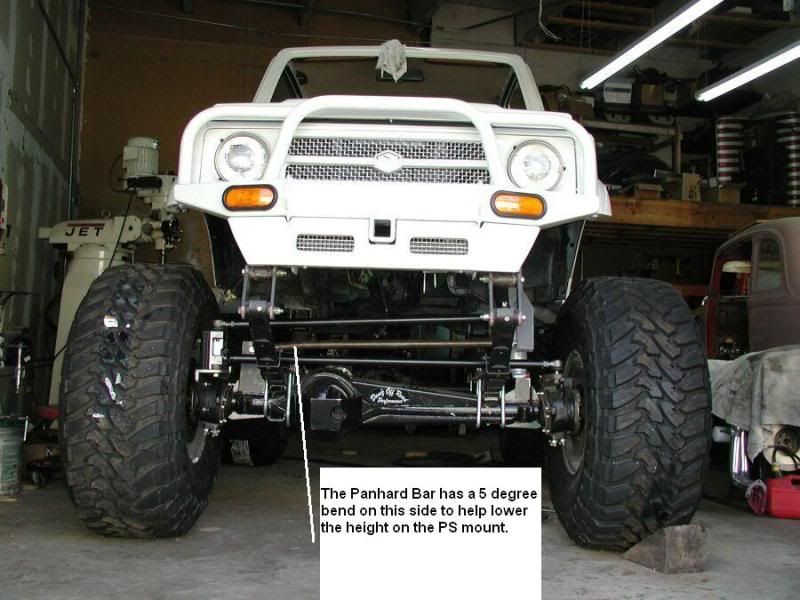

Shrockworks bumper and custom fiberglass valance

Rear View