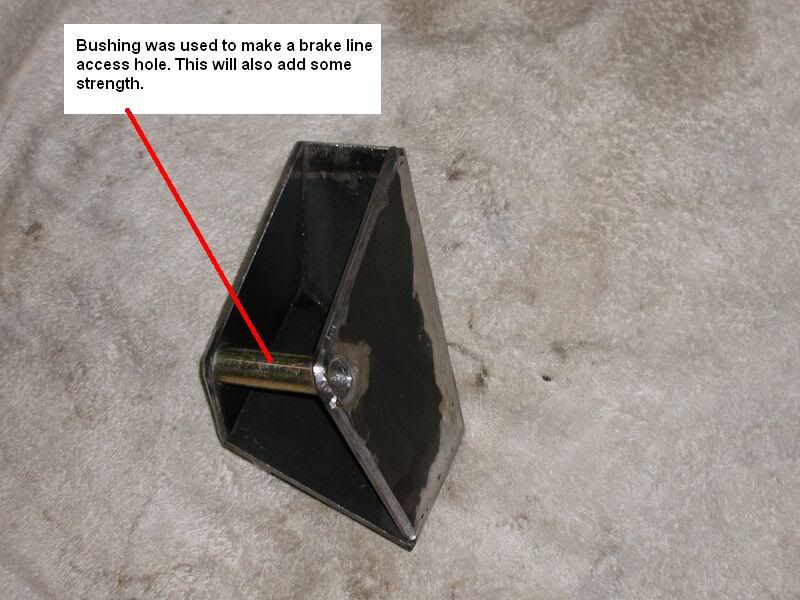

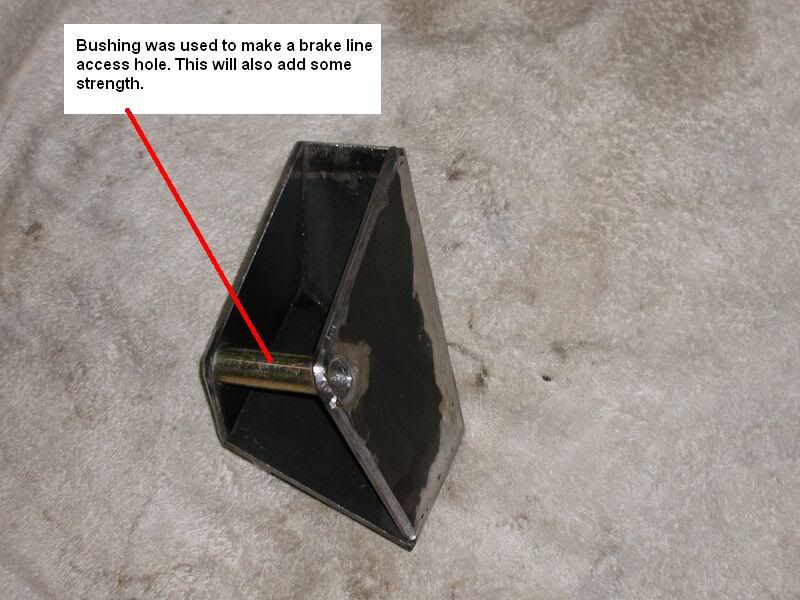

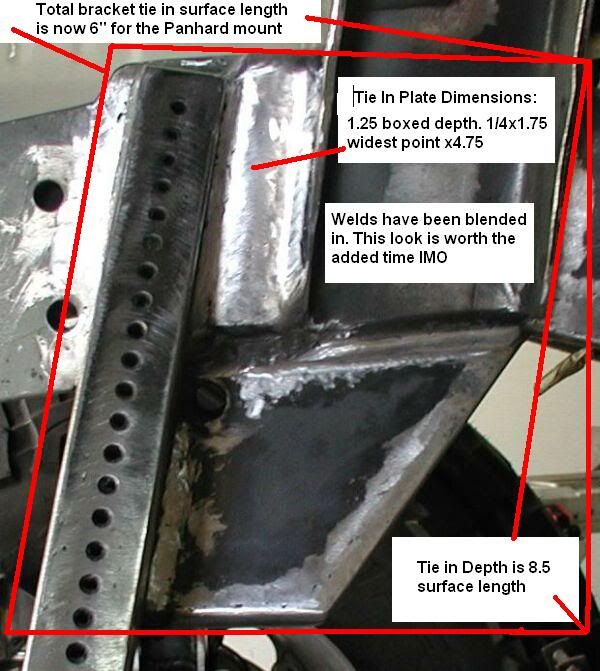

Here is a look at the large Panhard bracket which is a perfect example of a 3D trapezoid.

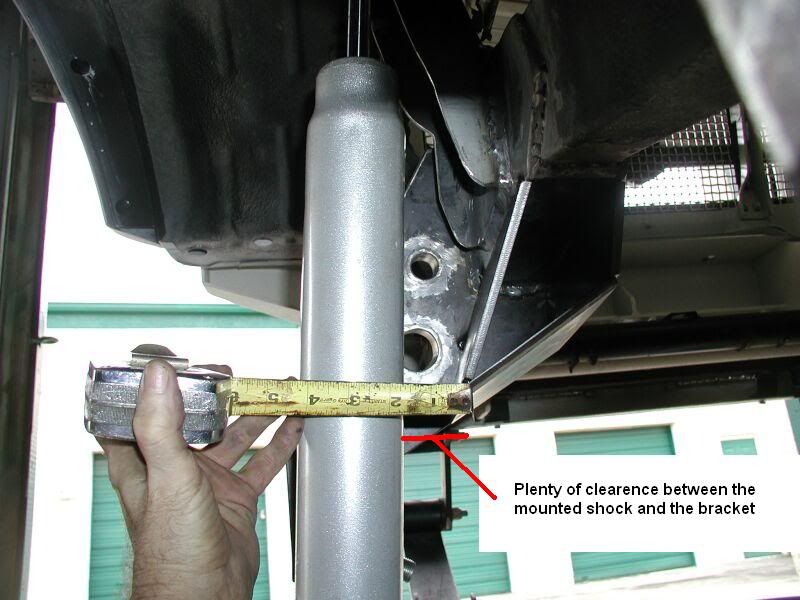

It took a little longer to complete after collaborating with Jethrobodean on the best structural strength of the bracket location. He had pointed out with the bracket blending in at the end of the fishplate. This would cause extra stress on this area. The better option would be to keep it 1 to 1.5” away from the end of the fishplate.

The choice was the shorter route to correct the problem because the plates were made already. The new position just happened to be my original thought. The strong need to make it more visually pleasing with everything blending at one place just took over.

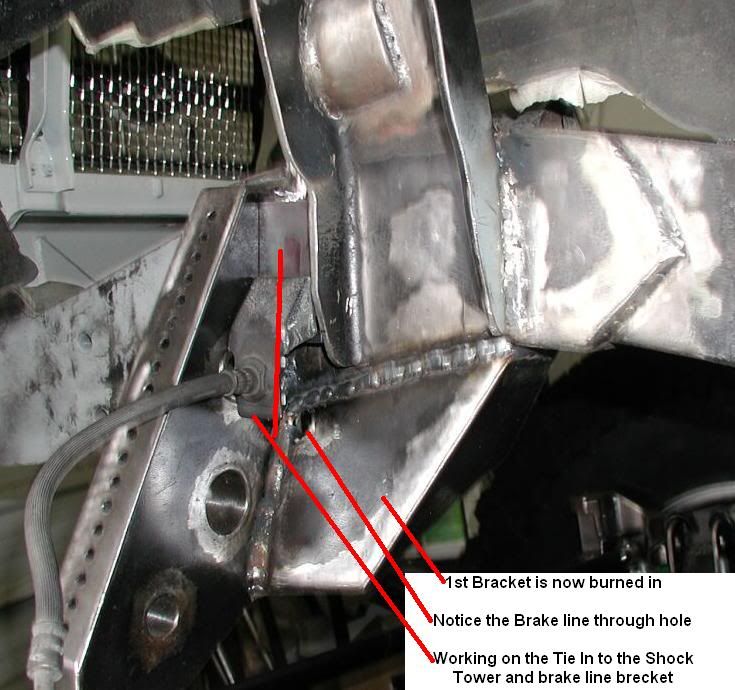

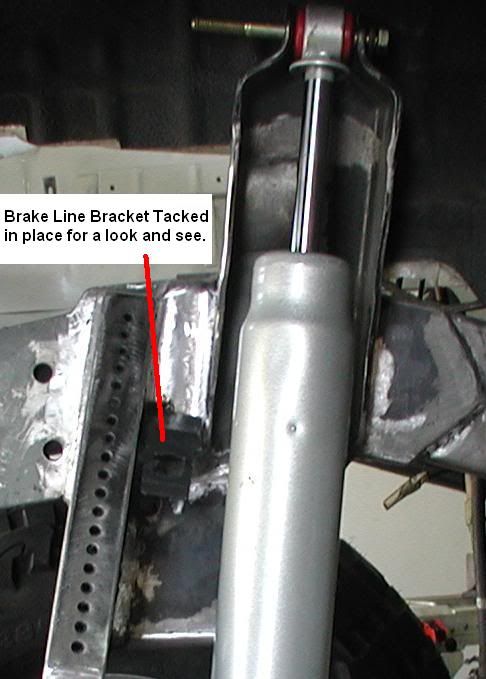

Jethrobodean also mentioned to add a fishplate to the backside of the bracket where it is being welded to the frame. This will be done as a precaution to eliminate the possibility of excess stress on this area. There was also mention to tie the top of the Panhard mount to the Ford Shock Tower for additional strength. All these were very good suggestions and will be performed as well.

Very Big Thanks to Jethrobodean for taking the time to point out something that I had contemplated on or over looked. It is always good to have an extra set of eyes looking at a complex design to accomplish the best out come.

Again it is better to be flexible ask for some input and make corrections on your design. This may require reworking or scrapping something that took a long time to make to address an issue.

You may be wondering why the tube bushing. It has been about 9 months or so since the original brackets were removed. Good thing I had remembered that the steel brake line had to have away to get to the brake line bracket. The tube seemed to be a good solution and give some more strength to the bracket.